Which floor is best for a garage?

For most car owners, a garage is a special place where you can not only leave your car overnight, but also spend hours on end doing minor car repairs. Many even turn the garage into a workshop and even a place to meet friends. Such multitasking puts forward special requirements for the decoration of the garage – everything must be done in it so that the car and its owner are completely safe and comfortable. The floor takes the greatest blow, because it is on it that the car will constantly drive, fuel and lubricants can spill on it and heavy tools can fall on it. The floor covering must withstand all these influences, so sooner or later every car owner wonders how to cover the floor in the garage. We hasten to offer you some of the best options.

WHAT SHOULD BE A FLOOR IN A GARAGE?

Not every flooring material can be used in a garage. The coating must meet the following requirements:

withstand regular loads from the vehicle weight. In addition, heavy tools are often stored in garages, which also exert pressure on the floor;

strength. The floor will bear not only loads from the car, but also from the fall of a heavy tool;

moisture resistance. When it is raining or snowing outside (and in some regions it is snowing for more than six months), a car on wheels and on the body will bring moisture into the garage, so the floor should not be susceptible to rotting and mold formation;

resistance to aggressive substances. Car maintenance involves the use of gasoline, cleaner, antifreeze, oil and other substances that, if they get on some materials, can damage them. For a garage, you should choose a coating that is not afraid of such effects and can be easily cleaned of stains;

resistance to fire, since there will always be flammable liquids in the garage;

resistance to temperature extremes. Most garages do not have heating, and the air warms up there only when the car owner decided to tinker with the car. This means that the floor covering will regularly suffer from temperature changes, and it is important that it does not crack or deform.

You can also add economy to the list of requirements, because, why dissemble, everyone wants to get the most by spending the minimum.

The requirements are strict, but car owners have a choice of suitable materials. Let’s try to figure out which garage floor is better, and what are the main pros and cons of popular materials.

SELF-LEVELING FLOORS

The use of self-leveling floors allows you to quickly get a perfectly flat surface. Mixes for self-leveling floors differ in composition and purpose. For example, cement and gypsum mixtures are usually used to level the floor. They do not allow you to create a decorative topcoat, but with their help you can very quickly and easily get rid of minor irregularities. Such formulations are inexpensive and fairly easy to use. For leveling the floor in the garage for finishing, it is better to use a cement self-leveling floor, since gypsum is sensitive to high humidity.

Another thing is polymer self-leveling floors, which are considered a topcoat. The basis for them will be a concrete screed, on top of which a cement self-leveling floor can be used, since the base must be perfectly flat.

The advantages of a polymer self-leveling floor include the following qualities:

- the durability of the coating, which is measured in decades;

- resistance to temperature extremes and frost, which is not uncommon in a garage;

- resistance to aggressive chemicals;

- fire resistance;

- moisture resistance;

- hygiene and ease of cleaning.

Minuses:

- high cost of coverage;

- difficulties in the repair process. If some area of the coating is suddenly damaged, then it will be problematic to repair it due to the difficulties with the selection of the desired shade.

- The properties of the coating will depend on the composition of the material used.

Polymer self-leveling floors.

Polyurethane floors are the most expensive ones, they require very careful preparation of the base, but at the same time they are distinguished by the greatest resistance to shock loads and vibrations. The coating perfectly tolerates the effects of aggressive substances, moisture, and the fall of heavy objects is not afraid of it. In addition, the coating is resistant to temperature extremes, it is easy to care for it, and cracks and scratches are relatively easy to restore – even if you manage to damage the floor, the place of deformation will need to be sanded and varnished on top. It turns out the ideal version of the floor in the garage, and the high price restrains the spread;

Methyl methacrylate flooring is great for a garage. The coating is durable, wear-resistant, moisture-resistant, withstands exposure to chemically active substances. In addition, the floor hardens very quickly, and within a few hours after the end of installation, you can walk and drive on it.

The disadvantage is a pungent smell during drying, but when organizing high-quality ventilation, it quickly disappears. During the operation of the coating, no extraneous odors will appear;

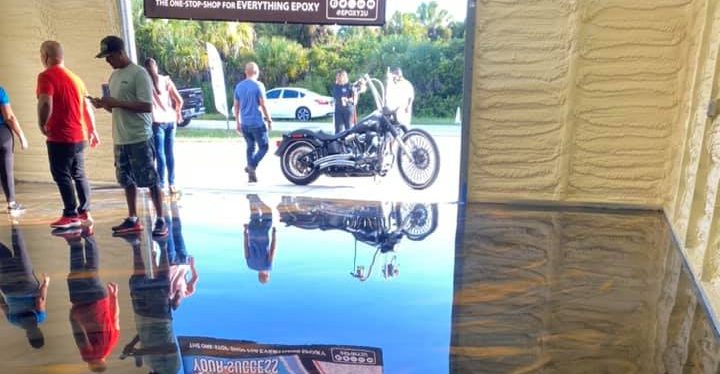

epoxy floors also tolerate abrasion well, exposure to moisture, corrosive substances, temperature extremes. The coating comes out hard and durable, but it has a significant disadvantage – it is afraid of impacts. Therefore, if you often make something in the garage and use a lot of heavy tools, then it is better to look towards other materials. If there are no particularly heavy objects that can fall in the garage, then an epoxy self-leveling floor is right for you;

a cement-acrylic floor is the same cement bulk floor, but its characteristics are improved due to the presence of a polyacrylate copolymer in the composition.

The coating turns out to be moisture-resistant, resistant to aggressive substances, non-slip, perfectly withstands mechanical stress, but due to low elasticity, cracks may appear on the surface.

A garage is not a place for fancy decor, but some car owners will still appreciate the opportunity to slightly transform a room where a sufficient amount of time is spent. Polyurethane and epoxy self-leveling floors can be painted in any shade, and if desired, even add decorative chips (paint particles of different shapes and sizes) to simulate the surface of granite, marble, etc. You can, of course, apply a drawing, use a 3D image, and put coins, sand or other decorative elements under a layer of a transparent floor, but this is hardly appropriate in a garage.

The main activity of the company is :

- building of the garages, hangars,

- epoxy floors, polishing of the concrete, industrial floors painting

- residential remodeling,

- building of decks, porches and stairs